How a Strapping Equipment Can Enhance Your Storage Facility Efficiency

In today's fast-paced warehousing setting, efficiency is crucial. Strapping Machine. You could discover that automating your strapping procedure can considerably improve operations. With the right maker, you can cut labor expenses and decrease bundle damage throughout transit. Not all strapping makers are created equal. Understanding what to look for and how to integrate these machines right into your existing workflow is crucial for maximizing their advantages. Allow's discover what makes a strapping maker an important device for your warehouse

The Function of Strapping Machines in Modern Warehousing

In today's busy warehousing environment, strapping equipments play a crucial role in improving effectiveness and efficiency. You count on these devices to protect bundles tightly, minimizing the threat of damages during transit. Instead of manually covering and strapping items, you can utilize computerized options that conserve time and decrease labor costs.Strapping equipments aid simplify your process by speeding up the packing procedure. They assure uniformity in just how items are bundled, permitting you to preserve high requirements in product packaging. You'll find that using a strapping equipment reduces the requirement for added products, thereby enhancing your supply chain.Moreover, these equipments are adaptable to different plan dimensions and shapes, making them flexible devices in your warehouse. By integrating strapping devices right into your procedures, you'll not only enhance performance yet also develop an extra effective and orderly work setting, allowing your team to concentrate on core tasks.

Benefits of Automating the Strapping Process

Automating the strapping process not only saves time but likewise substantially enhances your warehouse's overall productivity. By getting rid of hand-operated strapping, you decrease labor prices and reduce the threat of human mistake. This implies your team can focus on more vital tasks, improving process efficiency.Additionally, automated strapping devices regularly apply the right stress and safe and secure plans a lot more dependably, making sure that your products are well-protected during transportation. You'll observe fewer damaged items, which can bring about lowered returns and raised client satisfaction.Moreover, automating this procedure permits faster throughput, indicating you can ship more orders in much less time. This agility can give you a competitive edge in today's busy market. Generally, purchasing automated strapping streamlines your procedures, enhances precision, and can eventually result in greater earnings for your storehouse. Embrace this modern technology and view your efficiency rise.

Trick Functions to Look for in a Strapping Equipment

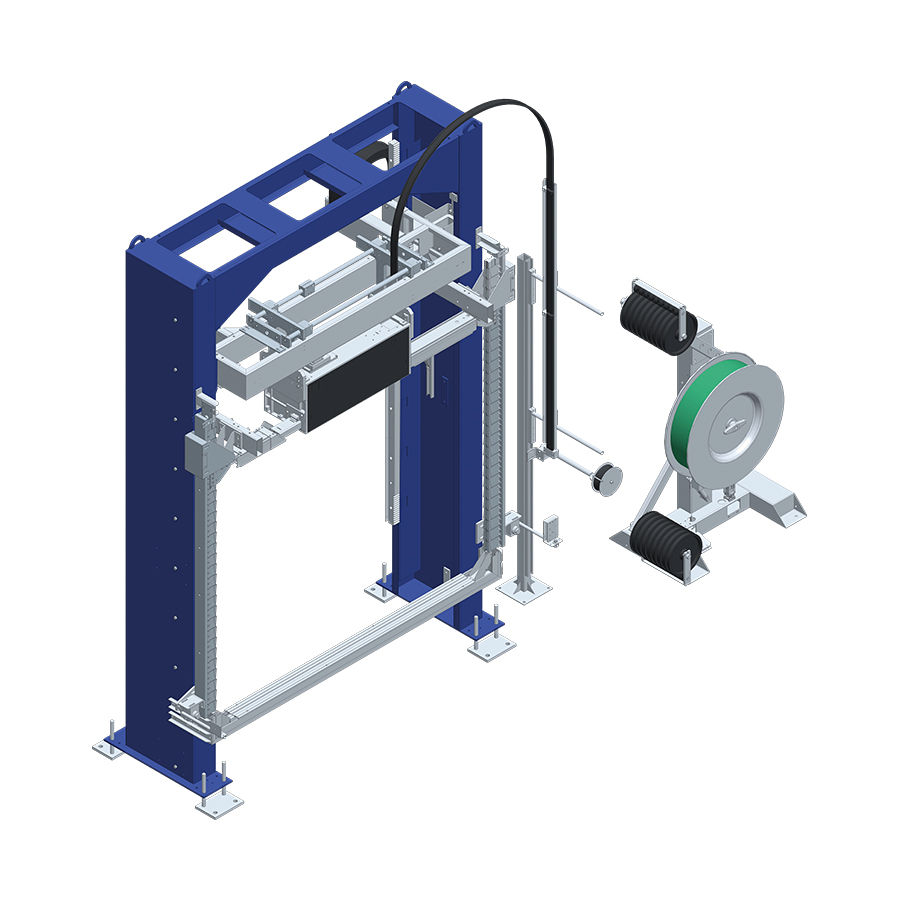

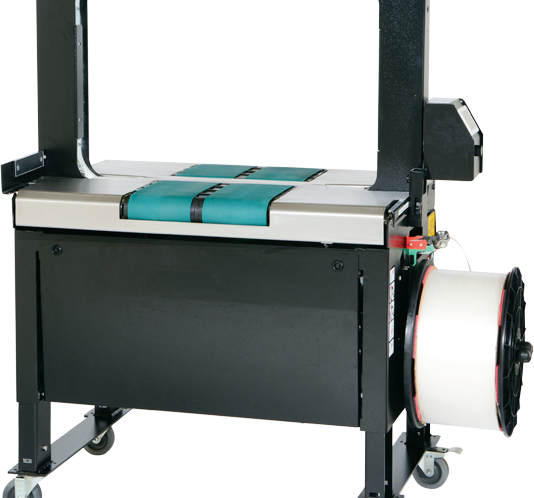

Kinds of Strapping Machines and Their Applications

Strapping devices been available in numerous kinds, each created to meet particular operational requirements in a storehouse. Semi-automatic strapping equipments enable you to manually feed the band while the device does the cutting and securing. This is suitable for lower quantity procedures where flexibility is vital. Then there are totally automatic equipments, best for high-speed environments. They instantly feed, tension, and seal bands, increasing performance markedly.Another choice is portable strapping devices, which supply wheelchair and simplicity for tight rooms or tiny jobs. Think about a heavy-duty strapping maker designed to manage bigger products firmly if you deal with hefty tons. Electrical strapping machines provide constant stress for consistent outcomes, making them a great option for high quality control. By understanding the different types, you can choose the ideal strapping maker that aligns with your storage facility's details demands, boosting total productivity.

Integrating Strapping Machines Into Existing Process

Incorporating strapping devices into your existing process can considerably enhance and simplify operations efficiency. Start by assessing your present packaging procedure to identify bottlenecks. Establish where strapping can include value, whether it's safeguarding boxes for delivery or packing products for storage.Next, pick the appropriate sort of strapping machine that fits effortlessly into your configuration. See to it it works with your packaging materials and can manage your quantity demands. Educating your team is necessary; they require to recognize just how to run the machine effectively and safely.Consider putting the strapping maker near to packing stations to lessen activity. In this manner, you'll reduce time invested in packaging tasks. Likewise, monitor the integration process and collect feedback from your group. Readjust as required to optimize performance. By attentively integrating strapping machines, you'll improve your workflow, lower labor expenses, and ultimately enhance overall warehouse effectiveness.

Case Researches: Success Stories From Storehouses

Effective storehouses frequently share stories of just how strapping devices changed their operations. For example, a large circulation facility dealt with hold-ups throughout peak seasons as a result of click hand-operated strapping methods. After presenting a fully automated strapping device, they saw a 30% rise in product packaging speed. Orders that when took hours to prepare were currently finished in minutes, enabling faster delivery and boosted customer satisfaction.Another storage facility accommodating shopping experienced frequent product damage during transit. By executing a strapping equipment, they safeguarded packages much more successfully, reducing damage prices by 40%. This not just conserved costs on replacements however also improved their credibility for reliability.In both instances, the introduction of strapping makers structured process and increased effectiveness. You can see exactly how these success tales illustrate the substantial advantages of updating your warehouse operations. Adopting this technology can be the trick to launching your warehouse's full potential.

Future Fads in Strapping Technology and Warehouse Efficiency

As you look ahead, think about just how automation and robotics are reshaping strapping technology in stockrooms. You're likely to see a change towards sustainable products and smart tech that enhances performance. Accepting these patterns can considerably boost your operational efficiency and ecological effect.

Automation and Robotics Integration

Sustainable Strapping Products

The promote higher performance in storage facilities works together with an expanding concentrate on sustainability, specifically when it comes to strapping materials. You can boost your procedures by choosing green options like biodegradable polyesters or recycled polypropylene - Strapping Machine. These materials not only decrease your ecological impact yet additionally maintain strength and dependability. By embracing lasting strapping, you reveal your dedication to green practices, which can improve your brand image and draw in ecologically aware consumers. Furthermore, numerous vendors are currently using cutting-edge alternatives that incorporate resilience with sustainability, ensuring you do not compromise performance. Changing to these materials can result in cost savings too, offered their possibility for minimizing waste and enhancing recyclability in your supply chain

Smart Innovation Advancements

With developments in smart technology, strapping machines are coming to be extra easy to use and efficient than ever. You'll locate features like real-time surveillance and automated adjustments that assist improve your operations. These machines can now incorporate with warehouse management systems, allowing for far better stock tracking and decreased errors. Picture being able to track each band's tension and top quality promptly, making sure peak performance without hand-operated checks. Additionally, anticipating analytics can forecast upkeep requirements, minimizing downtime. As you accept these developments, you'll not just increase performance however additionally improve workplace safety. Purchasing smart strapping modern technology is a smart selection for future-proofing your storage facility and remaining competitive in an ever-evolving market. Accept the change, and see your efficiency rise!

.jpg?width=600&height=600&name=FRP1000-%20Ask%20for%20Price%20(1).jpg)

Frequently Asked Concerns

What Is the Ordinary Lifespan of a Strapping Maker?

The ordinary lifespan of a strapping device commonly ranges from 5 to ten years, relying on use and maintenance. Routine treatment can expand its life, guaranteeing you get the most value from your financial investment.

Just How Much Maintenance Do Strapping Devices Need?

Strapping equipments call for regular maintenance to ensure peak efficiency. You need to inspect components regularly, tidy the machine, and replace worn parts as needed. Complying with the maker's standards will certainly aid you decrease downtime and extend the machine's lifespan.

Can Strapping Machines Deal With Different Strap Sizes?

Yes, strapping devices can deal with different strap sizes. You just need to adjust the setups or pick a machine designed for versatility. This adaptability assists you effectively handle numerous packaging requirements in your operations.

Are Strapping Machines Energy-Efficient?

Yes, strapping equipments can be energy-efficient. They frequently use less power than hand-operated approaches, lowering overall power usage. By choosing the right version, you'll conserve energy and lower expenses while keeping efficiency in your operations.

What Safety Includes Should Strapping Machines Include?

When picking a strapping equipment, you ought to look for attributes like emergency stop switches, websites security guards, and automatic stress changes. These improvements help shield drivers and keep a secure functioning atmosphere in your stockroom. You'll locate that making use of a strapping equipment minimizes the demand for extra products, consequently optimizing your supply chain.Moreover, these makers are adaptable to numerous package dimensions and shapes, making them flexible tools in your storage facility. When selecting a strapping equipment, it's vital to take into account numerous essential functions that can significantly affect your storage facility procedures. Semi-automatic strapping devices permit you to manually feed the strap while the equipment does the cutting and sealing. Training your personnel is vital; they require to recognize how to run the equipment successfully and safely.Consider putting the strapping equipment close to packing stations to decrease movement. Successful stockrooms typically share tales of how strapping devices changed their procedures.

Comments on “Top Add-Ons to Maximize Your Strapping Machine Investment”